Detail

In cleanroom technology, maintaining a controlled environment is critical to ensuring product quality and safety in industries such as pharmaceuticals, biotechnology, electronics, and healthcare. One of the key components in achieving this controlled environment is a laminar flow ceiling system. This innovative technology plays a vital role in creating a clean and germ-free environment by controlling air quality and minimizing the risk of contamination.

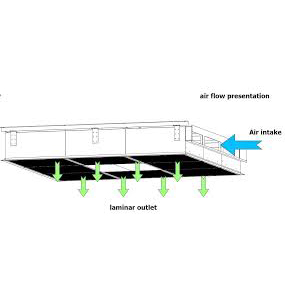

Laminar flow ceiling systems are designed to provide a continuous flow of ultra-clean air in a unidirectional pattern, ensuring effective removal of air particles from the environment. This is achieved through the use of high-efficiency particulate air (HEPA) or ultra-low permeability air (ULPA) filters integrated into the ceiling. These filters are used to remove contaminants such as dust, microorganisms, and other airborne particles, thereby creating a controlled sterile environment.

One of the main advantages of a laminar flow ceiling system is its ability to provide even and consistent airflow throughout the cleanroom. This is achieved through the use of specialized diffusers and airflow control mechanisms, ensuring air is evenly distributed throughout the space. As a result, the risk of turbulence and cross-contamination is minimized, creating an environment conducive to the production of high-quality and contamination-free products.

In addition, the laminar flow ceiling system features an energy-saving design with an advanced airflow management system that optimizes air usage and minimizes energy consumption. Not only does this reduce operating costs, it also helps create a more sustainable and environmentally friendly cleanroom facility.

In addition to their technical capabilities, laminar flow ceiling systems offer practical benefits to cleanroom operators. The system's modular design facilitates installation and maintenance, minimizing downtime and ensuring continuous operation. The ceiling is made of durable and easy-to-clean material suitable for use in a variety of cleanroom environments.

When selecting a laminar flow ceiling system, it is important to consider the specific requirements of your cleanroom facility. Factors such as the size of the cleanroom, the level of cleanliness required and the nature of the operations being performed will all influence the selection of the most suitable system. Additionally, compliance with industry regulations and standards, such as ISO 14644 and cGMP, should be considered when selecting a laminar flow ceiling system.

In conclusion, laminar flow ceiling systems play a vital role in creating and maintaining a clean and sterile environment across industries. Its ability to control air quality, minimize the risk of contamination and provide uniform airflow makes it an essential component of modern cleanroom facilities. By investing in a laminar flow ceiling system, companies can ensure the integrity and quality of their products while meeting the stringent requirements of cleanroom operations.

Product Description

The laminar flow ceiling is a dust-free aseptic purification equipment with high cleanliness. It can even create a class100 cleanliness work area environment,. What is more, It adopts high quality materials, for example, the box body is made of high quality cold rolled steel, and the sprinkler plate is optional stainless steel. The laminar flow ceiling is equipped with professional filter and box connection which supply the fresh air into the clean room. The air flows in vertical unidirectional way, and the wind speed of the air surface is stable, which effectively reduce the filter replacement cycle.

The Laminar Flow Ceiling is installed at the ceiling of Operating room to offer the uniform air flow and clean class, like for the class I clean operating room, class II clean operating room, class III clean operating room. It can ensures efficient protection against contamination which can occur during invasive acts and caused by airborne dead or living particles.

FEATURES

1.It can be used alone or several together.

2.A good sealing performance with professional filter and box connection.

3.The overall wind with uniform speed.

4.Low noise, smooth operation, easy to maintain and replace, cost effective.

Applications

It is mainly used in the hospital operating room to meet the requirements of different operating levels.

Specifications

|

All sizes and styles can be customized |

|||

|

Model |

BSL-LF01 |

BSL-LF02 |

BSL-LF03 |

|

Cabinet size(mm) |

2600*2400*500 |

2600*1800*500 |

2600*1400*500 |

|

Static cabinet material |

Steel with powder coated/Stainless steel |

||

|

Diffuser plate material |

Gauze/Steel with powder coated/Stainless steel |

||

|

Average wind speed(m/s) |

0.45 |

0.3 |

0.23 |

|

Filtration efficiency(@0.3un) |

99.99% |

||

|

Filter type |

Separator HEPA filter/V bank filter |

||

|

Use occasions |

Class I clean operating room |

Class Il clean operating room |

Class Ill clean operating room |

Home

Home Products

Products Contact Us

Contact Us News

News