Product Advantages

- Cross contamination control through negative pressure environment option.

- Full unidirectional airflow provides superior aseptic work zones.

- Fully welded single piece SUS304 internal chambers with rounded covered corners.

- Clean interior and exterior finishing.

- GMP modular design with minimized joints and seams.

- Gel seal HEPA filters, HEPA/ULPA gel sealed design is better than conventional gasket sealed.

- Dimensions are customized to suit process requirements.

- All components meet or exceed applicable safety requirements.

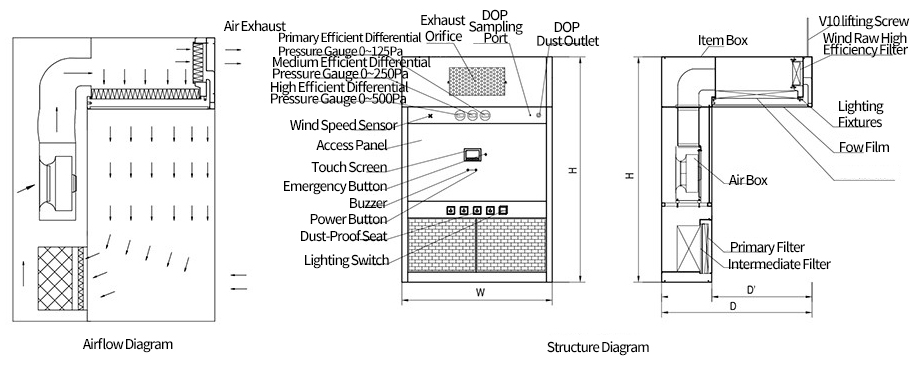

Technical Indicators

● The airflow velocity is 0.45m/s±20%.

● Equipped with control system.

● Wind speed sensor, temperature and humidity sensor Optional.

● High Efficiency fan modules provide clean laminar flow air (measured with 0.3µm particles) to meet cleanroom requirements with efficiencies up to 99.995%.

● Filter module:

● Primary filter - Plate filter G4;

● Medium effect filter - bag filter F8;

● High Efficiency Filter - Liquid tank high efficiency separator free filter H14.

● 380V power supply.

Product Drawing

Standard Size and Basic Performance Parameters

|

Model number |

Overall dimensionW×D×H |

Work area size W×D×H |

Wind speed on the outlet side(m/s) |

Cleanliness of work area |

Power supply(kw) |

|

BSL-WR 13-120060 |

1300×1200×2570 |

1200×600×2000 |

0.45±20% |

Cobackground region |

0.8 |

|

BSL-WR 34-150120 |

1600×1800×2570 |

1500×1200×2000 |

2 |

||

|

BSL-WR 75-200200 |

2100×2800×2570 |

2000×2000×2000 |

4 |

||

|

BSL-WR 112-300200 |

3100×2800×2570 |

3000×2000×2000 |

4 |

||

|

BSL-WR 186-400250 |

4100×3300×2570 |

4000×2500×2000 |

7.5 |

The shape height of the negative pressure weighing room is generally 20 ~ 30mm lower than the ceiling height of the room

Note: The specifications listed in the table are for customer's reference only and can be designed and manufactured according to customer's URS.

Introducing our innovative dispense chamber – weigh chamber and sampling system designed to revolutionize the pharmaceutical and research industries. Combining advanced features with cutting-edge technology, this product sets new standards for accuracy, efficiency and safety.

Our dispensing rooms – weighing rooms and sampling systems are designed to meet the stringent requirements of pharmaceutical preparation, quality control and research applications. It provides a controlled environment for dispensing and weighing various substances, ensuring that required quantities are accurately measured and maintained.

Our dispensing chambers – weighing chambers and sampling systems employ state-of-the-art filtration systems to ensure a contamination-free workspace, protecting the integrity of delicate substances and sensitive samples. HEPA filters remove even the smallest particles, maintaining a sterile environment and preventing cross-contamination.

Our systems are equipped with advanced weighing technology to ensure accurate measurements with minimal errors. Accurately calibrated scales accurately measure solid and liquid substances, delivering consistent results every time. This capability is critical for pharmaceutical companies and research laboratories because accuracy is critical to drug development and manufacturing.

Additionally, our dispensing chambers – weighing chambers and sampling systems are ergonomically designed for user comfort and convenience. The spacious interior provides ample workspace for multiple tasks, while adjustable lighting provides optimal visibility during all phases of the dispensing and weighing process.

Additionally, our systems feature an intuitive control panel that allows users to easily monitor and control various parameters. From adjusting airflow and lighting levels to setting individual user profiles, our distribution chambers – weighing chambers and sampling systems offer a user-friendly interface for seamless operation.

In conclusion, our dispensing chamber – weighing chamber and sampling system is a game changer, delivering unrivaled accuracy, reliability and safety for pharmaceutical and research tasks. By combining advanced functionality, reliable filtration mechanisms and precise weighing technology, this innovative product ensures optimal conditions for pharmaceutical preparation and research applications. Trust our Distribution Chambers – Weighing Chambers and Sampling Systems to revolutionize your workflow and take your operations to the next level.

Home

Home Products

Products Contact Us

Contact Us News

News