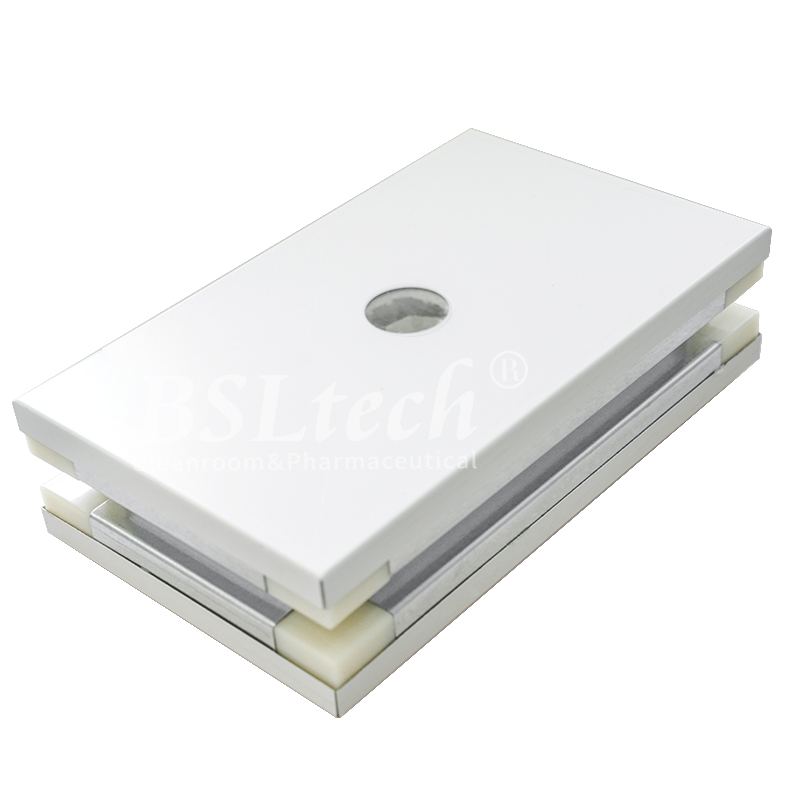

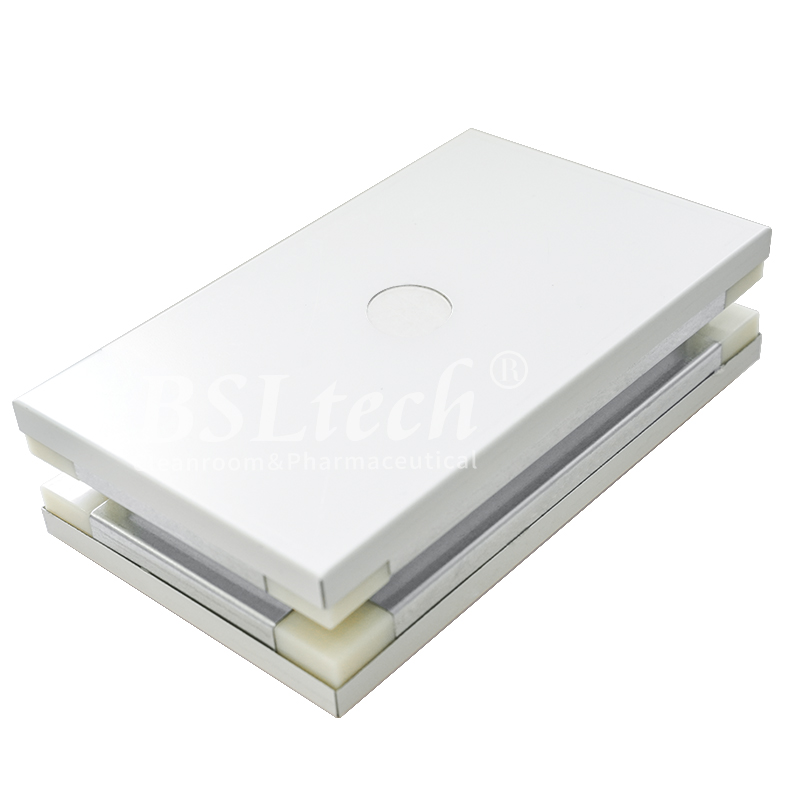

Product Specifications

|

Name: |

50mm Magnesium Oxysulfide Panel |

|

Model: |

BMA-CC-02 |

|

Description: |

|

|

Panel thickness: |

50mm |

| standard modules: | 950mm、1150mm |

|

Plate material: |

PE polyester, PVDF (fluorocarbon), salinized plate, antistatic |

|

Plate thickness: |

0.5mm、0.6mm |

|

Filled core material: |

Magnesium Oxysulfide(200kg/m3) |

|

Connection method : |

Tongue-and-groove board |

machine-made Magnesium Oxysulfide Sandwich Panel, a cutting-edge product of exceptional lightness and strength among building materials. The innovative panel uses color-coated steel plates as the surface layer and magnesium oxysulfide cementitious materials, magnesium oxide, magnesium chloride, flame-retardant EPS and other cementitious materials as the core.

Our magnesium oxysulfide sandwich panels usher in a new era of construction technology. Its unique composition provides excellent fire resistance due to the inclusion of flame retardant EPS material. This ensures a higher standard of safety, making it ideal for buildings requiring strict fire regulations.

One of the outstanding features of our panels is their incredible lightness. This lightweight construction material proved to be very advantageous as it reduced the overall load of the structure. reduces weight significantly while maintaining strength. This makes transportation, installation and overall construction easier and more cost-effective.

A color-coated steel finish enhances the panel’s aesthetics while providing exceptional durability and weather resistance. Steel plates ensure protection against corrosion and damage, ensuring a longer service life than traditional building materials.

Our magnesium oxysulfide sandwich panels are extremely versatile and are suitable for a variety of construction purposes. Whether it is a residential, commercial or industrial project, the panel has proven to be an excellent choice for a wide variety of construction types, from high-rise buildings to prefabricated houses.

All in all, our machine-made magnesium oxysulfide sandwich panels redefine the standards of building materials. The panels combine the strength of pre-painted steel with the superior fire resistance and lightweight properties of a magnesium-based core, ensuring superior safety, durability and cost-saving benefits. Upgrade your construction projects with our state-of-the-art panels and experience a whole new level of construction efficiency.

Home

Home Products

Products Contact Us

Contact Us News

News