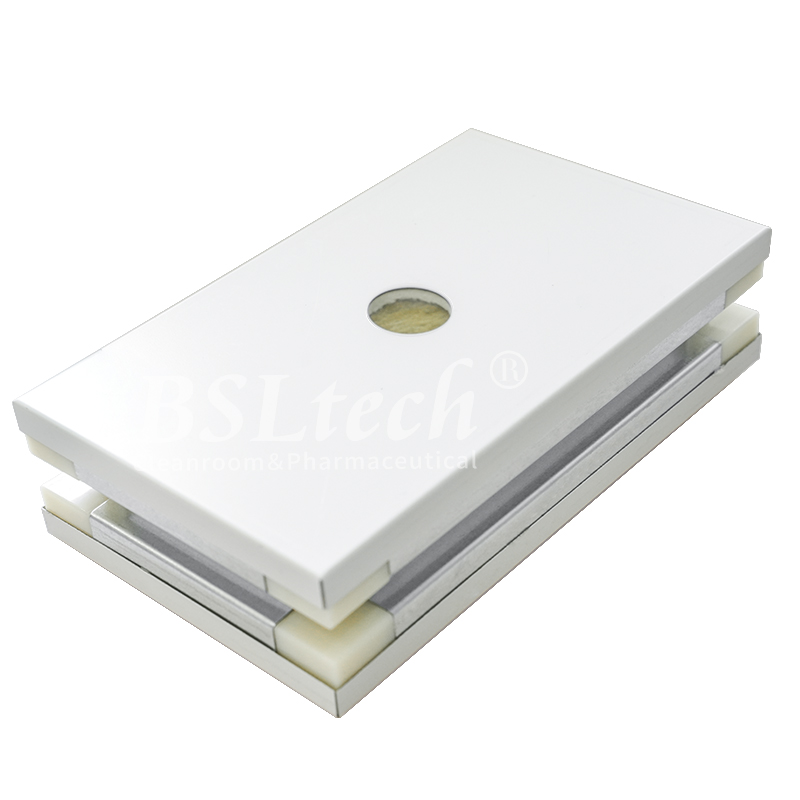

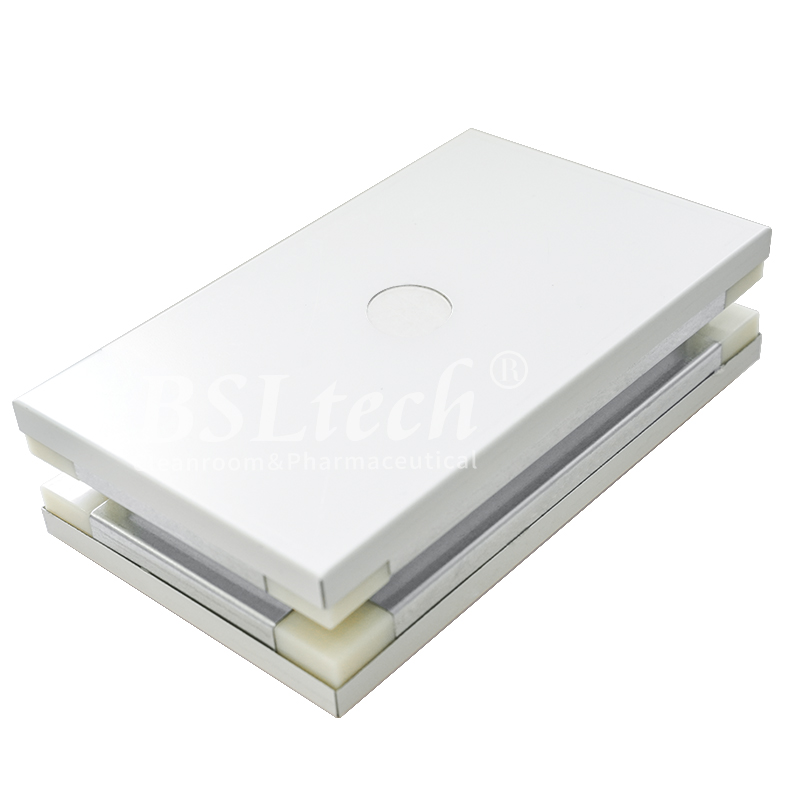

Product Specifications

|

Name: |

50mm Polyurethane Panel |

|

Model: |

BMA-CC-03 |

|

Description: |

|

|

Panel thickness: |

50mm |

| standard modules: | 950mm、1150mm |

|

Plate material: |

PE polyester, PVDF (fluorocarbon), salinized plate, antistatic |

|

Plate thickness: |

0.5mm、0.6mm |

|

Filled Core Material: |

Polyurethane(45g/m3) |

|

connection mothed : |

Tongue-and-groove board |

this Machine-made Polyurethane Cleanroom Panel offers unrivaled durability, ease of installation and a wide range of applications.

At the heart of ourcolour steel sandwich panels is a core material made of polyurethane sandwiched between two layers of high quality color steel panels. This combination of materials ensures excellent insulating properties while maintaining a lightweight construction. The polyurethane core acts as an effective thermal barrier, preventing heat transfer and maintaining a stable internal temperature.

Our panels are manufactured using high-speed contact automatic forming machines that use heat and pressure lamination to seamlessly bond the layers together. To ensure the perfect fit to your specific needs, the panels undergo additional steps such as trimming, notching and blanking.

One of the main advantages of our color-coated steel sheets is their light weight, which makes them easy to handle and install. In addition, our panels have a wide range of applications and are suitable for a variety of building structures, including cold storage facilities and cryogenic workshops.

In cold storage facilities, our color steel sheets provide effective insulation solutions to ensure a controlled temperature environment for perishable goods. The panel’s excellent heat resistance contributes to energy efficiency and helps reduce operating costs. Likewise, in cryogenic workshops, our panels offer the same insulation benefits, creating a comfortable working environment for employees while minimizing temperature fluctuations.

In conclusion, our high quality color coated steel panels with polyurethane cores are an excellent construction material choice for those looking for durability, ease of installation and versatility. Whether you are building a cold storage facility or a cryogenic workshop, our panels provide excellent insulation, reducing energy costs and ensuring a comfortable environment. Invest in our color coated steel panels and experience the difference in quality and performance.

Home

Home Products

Products Contact Us

Contact Us News

News