Product Specifications

|

Name: |

50mm Rockwool Panel | 75mm Rockwool Panel |

|

Model: |

BMA-CC-01 | BMB-CC-01 |

|

Description: |

|

|

|

Panel thickness: |

50mm |

75mm |

| standard modules: | 950mm、1150mm | 950mm、1150mm |

|

Plate material: |

PE polyester, PVDF ,salinized plate,antistatic |

PE polyester, PVDF ,salinized plate,antistatic |

|

Plate thickness: |

0.5mm、0.6mm |

0.5mm、0.6mm |

|

Filled Core Material: |

Rock wool (bulk density 120K) |

Rock wool (bulk density 120K) |

|

connection mothed : |

Tongue-and-groove board | Tongue-and-groove board |

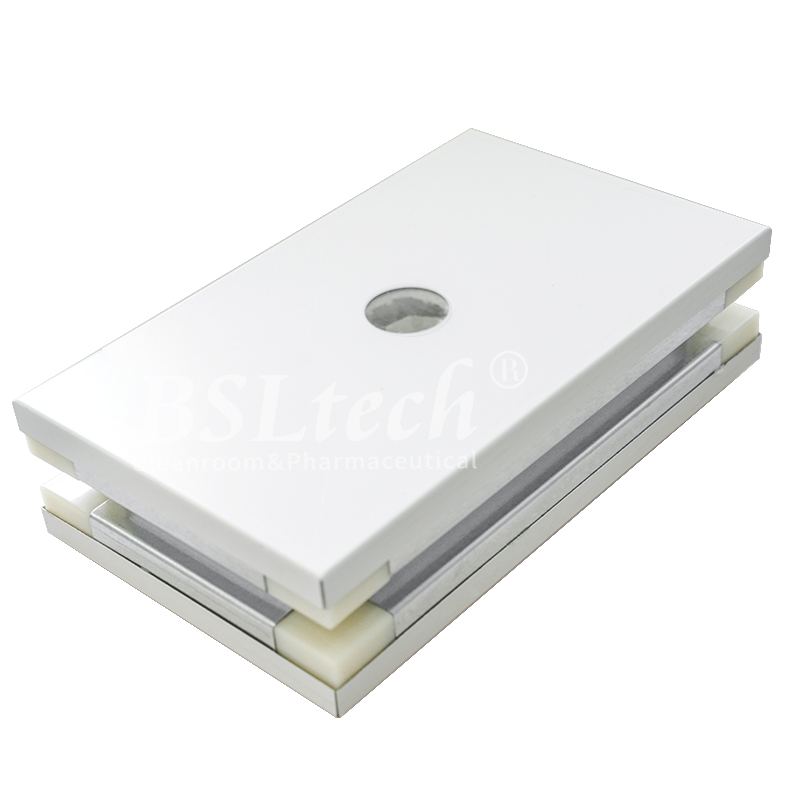

our machine-made rock wool sandwich panel, designed to meet the diverse needs of construction projects while ensuring maximum safety and efficiency. This product combines the durability of color steel plate with the excellent thermal insulation performance of rock wool, making it ideal for a variety of applications.

Machine-made rock wool sandwich panels are made of high-quality color steel plates, providing a strong outer layer that protects against external factors such as corrosion. The high-strength properties of color steel ensure that the panels maintain their integrity even in the harshest environments, making them suitable for both indoor and outdoor use.

The board core is composed of rock wool, which not only has excellent thermal insulation performance, but also has excellent fire resistance. This feature significantly increases the safety of any building project, as the panels are non-combustible, thereby reducing the risk of fire spreading and keeping its effects within a limited area.

One of the main advantages of our machine-made rock wool sandwich panels is their excellent thermal and insulating capabilities. The rock wool used in the panels acts as an excellent thermal barrier, minimizing heat transfer between the interior and exterior of the structure. This type of insulation helps maintain a comfortable and consistent temperature inside a building, reducing the amount of energy needed to cool or heat it.

The machine-made rock wool sandwich panel not only has excellent sound insulation performance, but also has excellent sound insulation performance. The rock wool core absorbs sound vibrations, reducing noise pollution and creating a tranquil environment within any structure.

Our machine-made rock wool sandwich panels are not only functional and efficient, but also beautiful. Available in a wide range of colors and finishes, pre-painted steel offers endless design possibilities to complement any architectural style.

The machine-made rock wool sandwich panel is non-combustible, has high thermal insulation performance and is durable. It is the best choice for construction projects that focus on safety, energy saving and comfort. Whether used in commercial buildings, industrial facilities or residential structures, this product guarantees high-quality building solutions that meet the industry’s most stringent standards. Trust our Mechanism rock wool sandwich panels to provide superior performance, reliability and longevity for your project.

Home

Home Products

Products Contact Us

Contact Us News

News