Product Specifications

|

Name: |

50mm Hollow Magnesium Panel | 75mm Hollow Magnesium Panel |

|

Model: |

BMA-CC-04 | BMB-CC-03 |

|

Description: |

|

|

|

Panel thickness: |

50mm |

75mm |

| standard modules: | 950mm、1150mm | 950mm、1150mm |

|

Plate material: |

PE polyester, PVDF (fluorocarbon), salinized plate, antistatic |

PE polyester, PVDF (fluorocarbon), salinized plate, antistatic |

|

Plate thickness: |

0.5mm、0.6mm |

0.5mm、0.6mm |

|

Filled core material: |

Hollow Magnesium |

Hollow Magnesium |

|

Connection method : |

Tongue-and-groove board | Tongue-and-groove board |

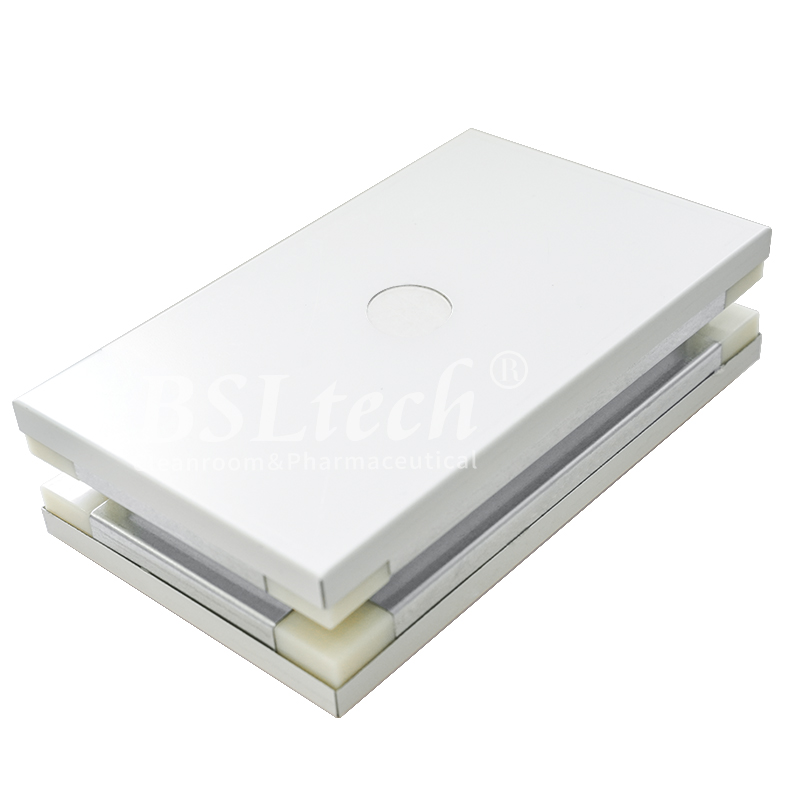

Machine-made Hollow Magnesium Sandwich Clean room Panel, combines high quality color-coated steel plate with a core made of hollow magnesium. This innovative product offers a variety of benefits, from moisture resistance to excellent heat absorption and non-flammability.

The surface layer of the machine-made hollow magnesium panel is made of high-quality color-coated steel plate to ensure that the outer layer is firm and reliable. Steel panels are coated with high-quality material for extra protection against wear and tear. Its sleek and smooth surface not only enhances the overall aesthetic of any space, but is also scratch and mark resistant, making it ideal for construction projects that require durability and longevity.

The hollow magnesium core material is the difference of this product. It is made of extremely light, high-strength fiberglass, which has excellent thermal insulation properties and effectively prevents heat transfer from its surface. Not only does this help maintain a comfortable indoor temperature, but it also saves energy by reducing the use of cooling and heating systems.

In addition, the machine-made hollow glass magnesium board has a moisture-proof design and is suitable for installation in places prone to moisture. Its unique composition acts as a moisture barrier, protecting infrastructure and preventing mold growth. This feature ensures that the product will remain in perfect condition over time, reducing the need for maintenance and repairs.

One of the most notable advantages of this product is its non-flammable nature. The combination of hollow magnesium and high-quality color-coated steel plates creates a highly fire-resistant structure. In the event of a fire, clean room hollow magnesium panels will not contribute to the spread of flames, providing valuable time for evacuation and possibly minimizing damage to surrounding areas.

In conclusion, the machine-made hollow magnesium panel is an excellent building material that perfectly integrates functionality, durability and safety. The moisture-resistant, heat-absorbing, and non-flammable properties of this product make it an excellent choice for a wide range of applications, including but not limited to residential, commercial, and industrial projects. Trust the superior quality and performance of hollow magnesium panels.

Home

Home Products

Products Contact Us

Contact Us News

News